Robotic Bending Cells: everything you need to know

During the last 10 years, industries across all sectors have actively participated in a significant...

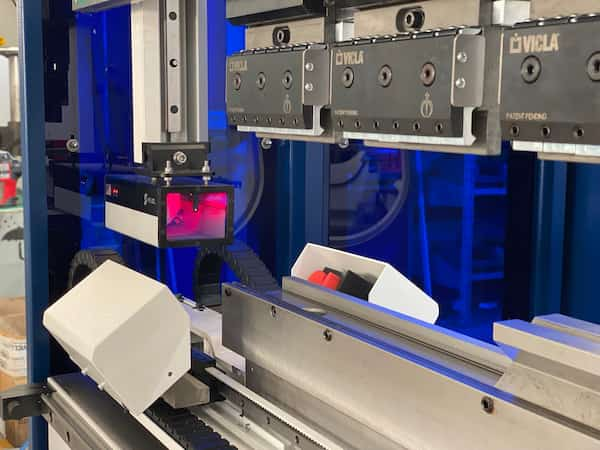

A robotic bending cell is a system that integrates a robot and a bending press, designed to perform operations of picking, bending, and depositing metal sheet profiles. It is a solution born out of the need for companies to make the production cycle more efficient while keeping production costs low without compromising quality.

The modern era of mechanical processes is characterized by a common thread: an increase in the level of quality in the repeatability of machining processes. In the field of sheet metal processing, continually improving productivity is one of the current major challenges, especially considering the growing variability in shapes, sizes, and quantities of pieces demanded by the market.

What are the possible solutions? As always, there is no one-size-fits-all formula, but there are options that better suit each individual company.

Today, we will talk about robotic bending and how it can enhance corporate productivity.

Bending automation has made significant strides compared to a few years ago, considering collaborative robots (cobots) or automated tool changer.

Before the advent of cobots and anthropomorphic robots, a Cartesian robot was used. This is a robotic arm that moves along a large steel frame positioned in front of the bending press.

Technological evolution in recent years has allowed freeing the robot from the elevated horizontal sliding beam, giving rise to the anthropomorphic bending robot.

The sheet metal processing sector is experiencing remarkable technological evolution, especially in the field of press bending. Traditionally, the bending phase has always been considered the bottleneck of the entire process because it is where the most significant waste occurs, both in terms of material and time.

Automated solutions act on two fronts: speeding up the bending cycle and reducing human error.

The automated bending cell relieves operators from strenuous, repetitive, and unstimulating work, allowing them to focus on other tasks.

VICLA automatic tool changer allows machine setup without operator intervention. Programmable remotely or on the machine, it accelerates the bending cycle.

In the new smart factory, the programming phase of different processing stages is managed by the technical office, which becomes the true operational center of the workshop.

With everything controlled from a single location, the bad habit of having programs in the machine more accurate than the technical drawings or relying solely on the notes of the benders ceases.

By reducing the discretion of the human factor, costs can be reduced. Positive impacts include a reduction in material waste and a decrease in the production cycle (operators can focus on optimizing other production cycles).

Additionally, the work of people involved in other areas is expedited.

Another aspect not to be overlooked is the safeguarding of the health of operators who, freed from taxing and dangerous activities, can engage in other tasks.

Operators can cease manual handling of large sheets, eliminate the risk of finger crushing during the bending phase, especially for very small pieces, and reduce risks and fatigue from manual tool changes.

Automation allows precise measurement of the time, material, and energy required to produce a piece. This enables more accurate quotations and eliminates the discretion of the human factor. How often does one base the price on skilled operators who are not always the same ones producing the piece?

Additionally, knowing in advance the timing, energy, and material, the company can make accurate forecasts of costs and revenues for the current year, improving the overall management of cash flows.

It is a common misconception to believe that automated bending will lead to the end of thousands of jobs. The same was said of the advent of the PC, but facts have shown that the introduction of new technology tends to have more positive than negative effects.

Bending automation will drive the development of human skills. New skills will range from machine maintenance to programming.

Thanks to the time saved, versatile figures capable of performing multiple tasks could emerge— for example, a laser cutter or a welder could learn to manage a robotic bending station much more quickly than a manual machine.

A robot can never replace the work of a highly skilled bender, also because not everything can be automated. There are indeed processes so complex that they must necessarily be carried out by the human hand.

As advanced as bending robots may be, they cannot understand if they are working correctly and if the piece is successful. To avoid unpleasant situations where the system worked all night and one ends up with a series of pieces that have errors and inconsistencies, it is necessary to equip oneself with sensors and bending control systems.

The first is angle control. It consists of a system of laser readers running parallel to the bending bench. This solution guarantees the set angle without any additional correction.

Another useful precaution that ensures the correct positioning of components is the rear register sensor system.

Other very useful devices are inserted inside the bending bench and serve to detect and compensate for natural flexions due to the bending effort.

Ensures excellent results and requires no in-depth technical knowledge; adjusts compensation without any need for operator intervention; guarantees a perfectly linear bend even on non-uniform materials (e.g., mixed perforated/solid material).

Device for controlling structural flexions of shoulders (VICLA Flex) allows maintaining the same bending depth regardless of the sheet metal's length.

The CNC receives data from the pressure sensors of the cylinders, which are then interpolated to establish the correction to be made.

As with any other machinery, it would be wrong to think that a robotic bending cell can do anything.

These are application limits that must be known and explored before proceeding with the machinery purchase, so as not to end up dissatisfied with the investment made.

Looking at the issue from another perspective, the question to ask is: what factors should be considered when choosing an automatic bending system?

The essential prerequisite is that the work is repeatable, so it cannot include prototyping. This is because it makes no sense to invest time in programming a product that will be made only once and never again.

If a workshop regularly produces different parts for customers, however, the program can be easily recalled, and it might make sense to invest in a robotic bending cell.

Furthermore, to get the maximum benefit from an automated system, it is crucial to ensure maximizing the variety of operations that can be performed on it.

What are the best jobs for a robotic bender? Surprisingly, it covers a fairly wide range of applications:

The cost of an automated system is certainly important, and it is undeniable that, for the same price, one could purchase one or more independent bending machines. However, the significant limitation of this reasoning is that, for each bending machine, an operator is needed. Are we sure the game is worth the candle?

When introducing an automated bending system, it is possible to optimize human resources as well. An experienced operator can manage an independent bending machine while monitoring a robotic cell.

In addition to choosing the right-sized tooling, a workshop must also consider how the parts will be removed from the cell. Will they be assembled into kits, placed on a conveyor belt, removed via a chute, or stacked on pallets?

Decisions like these will influence the length and width requirements of the cell.

It is a misconception to believe that merely programming in the technical office, hitting start, and waiting for the system to do all the work is sufficient. This oversimplification disregards the variables involved in sheet metal processing.

With a traditional bending machine, the operator can manually intervene to manipulate the piece and avoid potential collisions. In the case of a robotic system, the automated bending machine will only perform what it is programmed for, so the tool configuration must be precise.

A tool out of place could cause significant damage. It is crucial for the operator of the bending machine to ensure that every part is in its proper position because the robot cannot reposition the part to accommodate a misplaced tool.

In conclusion, working with a robotic bending machine requires meticulous attention to detail.

During the last 10 years, industries across all sectors have actively participated in a significant...

In an industry where precision and speed are paramount, angle control has become an indispensable...

The ever-increasing demand for skilled pressbrake operators, who possess both practical know-how...