EVB Metalwork Fabrication, specializing in contract machining, has consistently prioritized machinery innovation to fuel its growth and evolution.

One such example is their partnership with VICLA, which introduced the .Superior hybrid press brake to their workshop – a machine renowned for its ease of use and exceptional precision, perfectly suited for EVB's complex machining operations.

EVB's history is a testament to its growth from a small, family-owned workshop in the 1960s to a respected player in the sheet metal working sector. Marco Butti, the company's current owner and grandson of the founder, shared insights into this journey, the challenges faced, and the pivotal role of technology, particularly the collaboration with VICLA, which marked a new era of success and innovation for the company.

"EVB Metalwork Fabrication was established in the 1960s and primarily focused on third-party metalwork services, including laser cutting, bending, and part assembly," explained Marco Butti.

"Initially focused on repairs and small jobs, the company has successfully adapted to market demands, technological advancements, and expanded its service offerings. We have always strived to evolve our metalwork products, emphasizing quality over quantity."

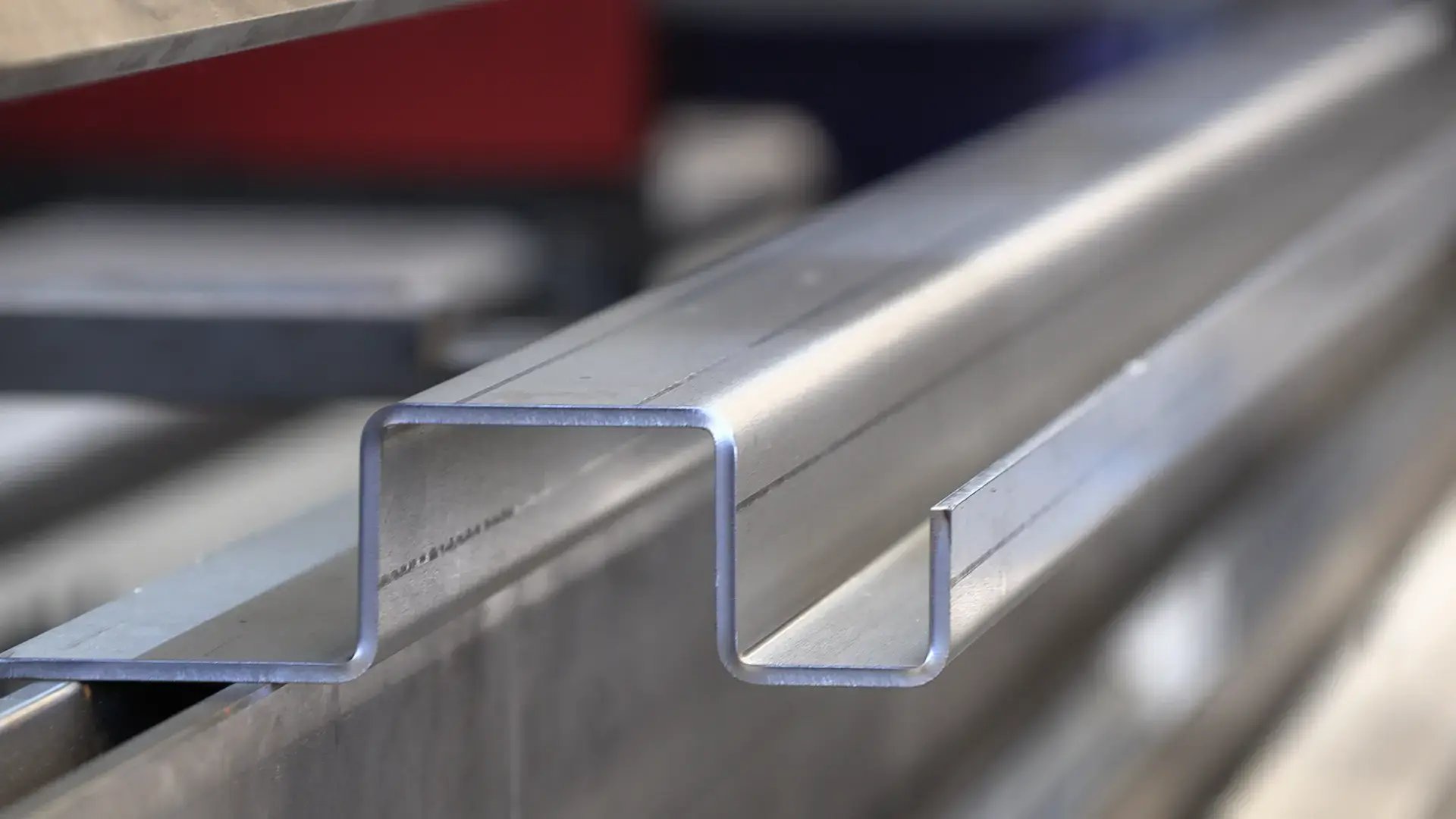

The diversity of work EVB handles is a testament to its strength, ranging from small 1 kg parts to 25-meter-long plinths. This flexibility enables the company to consistently meet customer needs and maintain high productivity.

Investing in Technology for Efficiency: Hybrid Press Brake

Investing in Technology for Efficiency: Hybrid Press Brake

Butti also highlighted a common challenge in the manufacturing sector: the shortage of skilled workers.

"Jobs are becoming increasingly complex, and there's a dwindling pool of skilled workers," he observed. In response, EVB has invested in new technologies and modern machinery to ensure efficiency and quality in their work. "Over the years, we've consistently updated our equipment," he confirmed.

A significant milestone in EVB's modernization was the collaboration with VICLA, a machine tool manufacturer. VICLA's .Superior hybrid press brake has elevated EVB's production standards. Butti noted,

"The .Superior, being a highly innovative machine, is remarkably intuitive and fast, even for those with limited bending experience."

This insight translated into a noticeable improvement in productivity.

The need to modernize their equipment became even more apparent when the operator of their previous bending machine retired. "The old machine was barely usable," admitted Butti. To assess the new technology, EVB brought their own test parts to VICLA.

"They provided us with the .Superior press, we brought our own equipment, and spent half a day producing at VICLA," said Butti, describing a fruitful collaborative experience.

The results were impressive: "We noticed a completely different way of working: machining was done with greater productivity," he added.

The new machine enabled EVB to tackle previously complex workpieces with ease, even empowering less experienced employees to work efficiently.

"The operator only needs to know how to use a smartphone to start bending with the VICLA press."

Marco Butti emphasized that the new technology has made it possible to produce parts that previously required significant operator expertise.

"Now we can make them with much less hassle and time wasted on checking each individual part," he said.

The VICLA press brake, in particular, has been instrumental in solving critical bending operations for paint plant conveyor tracks. These tracks demand precise tolerances and are complex to bend, being 1.5 to 3 meters long with narrow bends.

Thanks to the precision of the VICLA machine, EVB has achieved higher output than before. The machine has simplified work not only in terms of time but also in terms of physical effort for operators. The attendant can follow the bending process step-by-step, ensuring greater accuracy and reducing operator strain.

Hybrid Technology for Maximum Precision

Hybrid Technology for Maximum Precision

The VICLA .Superior hybrid press brake is designed to meet the precision and versatility requirements of modern production environments. Its robust and technologically advanced design ensures high performance and exceptional bending quality.

One of its distinctive features is its hybrid configuration, which combines energy efficiency with superior performance. The electric drive system reduces energy consumption and promotes environmental sustainability, a crucial factor in today's industrial landscape.

The .Superior is equipped with an advanced numerical control system for intuitive programming and easy operation. Operators benefit from a user-friendly interface that facilitates the input of machining parameters and the management of bending programs. This aspect has been highly appreciated by EVB and is a key strength of VICLA technology for Italian metalwork fabrication companies. Additionally, the machine integrates with CAD/CAM systems for seamless project management and production continuity.

Other notable features of the .Superior include an automatic bending angle correction system, which guarantees accurate and repeatable results. This technology optimizes production processes, increases efficiency, and minimizes scrap.

The .Superior bending brake is also designed to handle a wide range of materials and thicknesses, making it suitable for various industrial applications. This versatility is particularly valuable for subcontractors like EVB, who prioritize flexibility in their offerings. The machine's compact and versatile design also optimizes workspace, a significant advantage in the Italian industrial landscape where space is often limited and expensive.

VICLA Bending Machines: A Partnership for Innovation

Looking ahead, Butti confirmed that EVB continues to explore new investment opportunities in technology and strategic partnerships. While they considered acquiring a smaller press brake, personnel limitations presented a challenge. Despite these hurdles, their commitment to growth and innovation remains steadfast. "The next purchase in this sector will still be VICLA," said Butti, highlighting the fruitful partnership that has laid the foundation for future success.

EVB Metalwork Fabrication's experience and collaboration with VICLA exemplify the importance of investing in technology and innovation to maintain competitiveness in today's market. With a focus on the future and a strong commitment to quality and efficiency, EVB continues to be a model of how tradition can evolve to meet the new challenges of the modern industrial world.