Our story: press brake manufacturer

The Dawn of Hybrid Bending: A VICLA Story

“Hybrid bending? That'll never work." The initial feedback Marcello Ballacchino and Corrado Nucci—co-founders and partners of VICLA srl—received was seemingly discouraging. But for those familiar with the industrial sheet metal bending sector, it's well-known that sometimes you have to challenge old axioms and embrace new challenges.

In 2012, people were just starting to talk about electric bending machines, but very few had heard of hybrid technology applied to press braking.

Since then, thanks to the growing green trend in other sectors—especially automotive—significant strides have been made in raising public awareness about new energy-saving technologies..

Marcello Ballacchino - CEO & Founder of VICLA

Marcello Ballacchino, CEO & Founder of VICLA, tells the incredible story of VICLA, founded in 2008 and quickly establishing itself in the international landscape of sheet metal machine manufacturers.

Brianza, the Cradle of Italian Press Braking

Everything began in Brianza, the heart of Italian bending, where companies were born that over time elevated the reputation of Made in Italy in the field of press braking. However, few of those companies have survived the test of time and a changing world: technological, customs, and logistical revolutions have led to constant transformations and shifting landscapes.

In this process, VICLA has followed two paths that have defined its course: on one hand, an emphasis on Italian production, from initial consulting to final installation; on the other, constant innovation.

Connecting the Dots

VICLA was founded in 2008. After a brief period as importers, in 2012 they specialized in the design and construction of custom-made press brakes and shears tailored to individual company needs.

Made in Italy production is not the only characteristic that sets the Albavilla-based company apart.

The first Italian hybrid press brake was born right at VICLA and is now one of the most appreciated machines for speed, precision, and reliability. The differentiating idea comes directly from years of experience in the field, as Ballacchino explains:

It's well known that the bending department is often considered the 'bottleneck' of the production system, because it's where all the variability of the sheet metal emerges, often causing non-conformities, errors, and sometimes even inefficiencies.

We wanted to address this problem with a different approach, and to do so, we had to think of a new press brake, different from what the market already offered..

Marcello Ballacchino - CEO & Founder of VICLA

The First Made in Italy Hybrid Press Brake

In 2012, .SUPERIOR was born, the first 100% Made in Italy hybrid press brake.

.SUPERIOR marked a turning point compared to the axioms rooted for years in the world of press braking: it's not just one of the fastest bending machines on the market, but it's above all the first true hybrid bending machine built and designed in Italy. The uniqueness of this machine lies in the winning combination of technological innovation and mechanical precision, which allows for rapid production cycles, positioning precision, and high energy efficiency.

Pioneers of Innovation, press brake manufacturer

“If you're an entrepreneur, you know you can't stand still, you die. Innovation is needed in all sectors, especially where you think there's less need for it.

And you and I, as entrepreneurs, today more than ever are called to play the role of continuous innovators.»

Marcello Ballacchino - CEO & Founder di VICLA

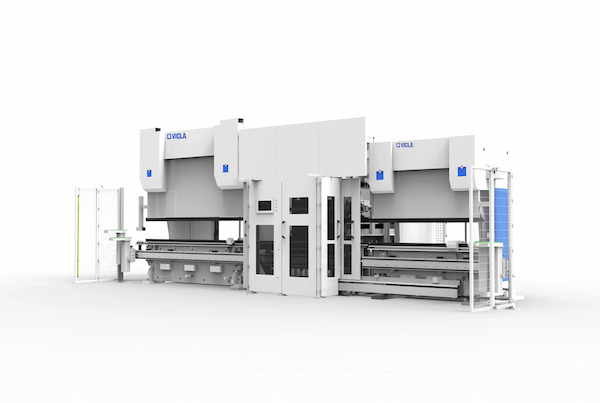

VICLA has made innovation its hallmark: in a constantly evolving market, the secret to growth is to anticipate where the wind of innovation is blowing. Thanks to this overwhelming energy, which is part of the company's DNA, in 2019 VICLA designed the automatic tool changer connected to two press brakes.

This is the first company at the European level to have designed and implemented a solution that connects two hybrid bending machines with a fully automated tool magazine, confirming, once again, the pioneering spirit of the Brianza-based company.

Looking to the Future

Today, VICLA looks with interest at the themes of the Smart Factory. Robotic bending, automation, data analysis, and remote programming are just some of the features that distinguish the new generation of VICLA sheet metal machines.

With one constant: always maintaining a tailor-made approach in every project. This is why VICLA defines itself as an Industrial Atelier of Bending: an oxymoron, certainly, but one that hides a clear vision of the company.

Atelier for the care towards the customer and the tailor-made approach with which the machines are designed..

Industrial because the company invests countless hours in the development of new technologies, in line with the models of the Intelligent Factory..

The considerable national and international success of VICLA has necessitated expanding its operational spaces. In 2022, VICLA inaugurated its new headquarters, still in Albavilla, for an estimated increase in production capacity of around 100%..

“The expansion of the headquarters is a strategic operation that will lead us to increase our production capacity in terms of space, personnel, resources, and materials, and to internalize processes that were previously outsourced, for capillary control of the entire production and assembly chain.“

Marcello Ballacchino - CEO & Founder of VICLA

In the new headquarters, a modern building houses the production areas and offices. The new investments include, in addition to the new production area, the installation of a new Soraluce Boring Machine, which allows for further raising of quality standards and reducing processing times.

This demonstrates that looking ahead is the only thing that matters for doing business.